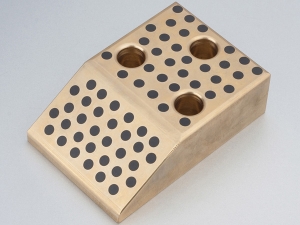

Solid Lubricated Bronze Overrun Cams

1. The #50WP solid lubricated bronze overrun cams adopt specially-formulated high-strength brass as base material. Surface of the oil-free slide plate product is inlaid with special solid lubricant according to specific angle and density.

2. As a kind of cam dwell wear plate, this product can be used under self lubrication condition without any refueling device. The sliding plate with solid lubricant can not only shorten assembly time, but also reduce oil pollution and beautify the environment.

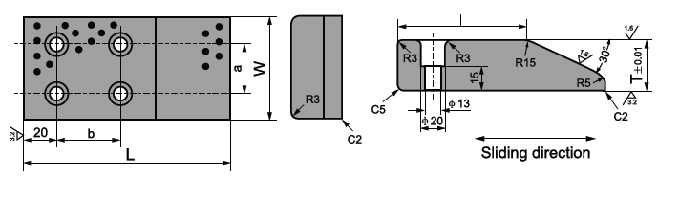

3. Please choose the part number according to the required width and length.

4. Here is an example. The ordering code of the solid lubricated bronze overrun cam is DNB-#50Wp-75130 under condition of 75mm width and 130mm length.

Technical Parameters

| Part No. | Width | Length | Thickness | I | a | b |

| 75 | 130 | 30 | 95 | 40 | 50 | |

| " | 150 | 45 | 90 | " | 45 | |

| " | 170 | 60 | " | " | " | |

| " | 200 | " | 120 | " | 75 | |

| 100 | 130 | 30 | 95 | 60 | 50 | |

| " | 150 | 45 | 90 | " | 45 | |

| " | 170 | 60 | " | " | " | |

| " | 200 | " | 120 | " | 75 | |

| 125 | 130 | 30 | 95 | 85 | 50 | |

| " | 150 | 45 | 90 | " | 45 | |

| " | 170 | 60 | " | " | " | |

| " | 200 | " | 120 | " | 75 | |

| 150 | 130 | 30 | 95 | 110 | 50 | |

| " | 150 | 45 | 90 | " | 45 | |

| " | 170 | 60 | " | " | " | |

| " | 200 | " | 120 | " | 75 |

Material |

#50SP1-SL1 CuZn25Al6 FeMn3 |

#50SP1-SL4 CuZn25Al6 FeMn3 |

#50SP5-SL1 CuZn25Al6 FeMn3 |

#50HP CuZn25Al6 FeMn3 |

#50AB-SL1 CuAl10Ni |

#50AB-SL4 CuAl10Ni |

#50B CuSn12 |

| Cu | 65 | 65 | 65 | 65 | 80 | 80 | 88 |

| Sn | 12 | ||||||

| Pb | 25 | 25 | 25 | 25 | |||

| Zn | 6 | 6 | 6 | 6 | |||

| Ni | 5 | 5 | |||||

| Al | 10 | 10 | |||||

| Fe | 5 | 5 | |||||

| Mn | 4 | 4 | 4 | 4 | |||

| Hardness HB |

>180 | >180 | >235 | >250 | >150 | >150 | >80 |

| Tensile strength N/mm² |

>550 | >550 | >750 | >785 | >200 | >200 | >200 |

| Elongation % |

>12 | >12 | >10 | >10 | >8 | >8 | |

| Coefficient of expansion |

1.9×10-5/℃ | 1.9×10-5/℃ | 1.9×10-5/℃ | 1.6×10-5/℃ | 1.8×10-5/℃ | 1.8×10-5/℃ | |

| Limited Temp ℃ |

300~400 | 300~400 | 300~400 | 400 | 400 | 400 | |

| Max load N/mm² |

80 | 100 | 118 | 50 | 70 | 70 | |

| MAX SPEED M/min |

15 | 15 | 10 | 20 | 10 | 10 | |

| Max PV N/mm2*m/s |

200 | 200 | 200 | 200 | 200 | 200 | |

| Compression set amount 400 N/mm² |

<0.01 | <0.01 | <0.05 | <0.04 | <0.05 | <0.05 |

Chinese

Chinese English

English Português

Português Русский

Русский Español

Español Deutsch

Deutsch