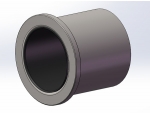

Bimetallic Bearing with Steel Shell and Sintered Bronze Lining

The bimetallic bearing has steel shell and sintered bronze lining. Its base material is high-quality low-carbon steel. Surface of the composite bearing is sintered with low-friction copper alloy including CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu and CuSn8Ni.

As a wear-resistant layer of the bimetallic bearing, the copper alloy surface can be designed with all kinds of oil grooves, oil holes and oil pockets on basis of specific working conditions. It is perfect for use in case of difficult refueling. Materials can be provided with superb binding strength and the optimum carrying capacity by means of secondary sintering and secondary squeezing technology.

Applications

1. Engineering Machinery

The bimetallic bearing for engineering machinery is applicable to the tension wheel bush, towing wheel bush, and the track roller bush of chassis running gear.

2. Automotive Industry

As a kind of automobile bearing, this product can be used in the balance shaft bushing, steel pin bushing, knuckle pin bushing, connecting rod bushing, valve rocker arm bushing, camshaft bushing, differential bushing, transmission bushing, thrust washer, and the main shaft bushing of internal combustion engine.

3. Other Applications

In addition, this product is ideal for use in the side panels of plunger pumps and the side panels of gear pumps, etc.

Physical and Mechanical Properties

| Maximum Dynamic Load Pressure, P | 140N/mm² | Mating Shaft | Hardness | ≥53HRC | |

| Maximum Line Speed, V | Grease lubrication | 2.5m/s | Roughness | Ra=0.16 ~0.63 | |

| Maximum Line Speed, V | Fluid lubrication | 5m/s | Maximum Operating Temperature | Grease lubrication | 150℃ |

| Maximum PV Value | Grease lubrication | 2.8N/mm²·m/s | Oil lubrication | 250℃ | |

| Maximum PV Value | Fluid lubrication | 10mm²·m/s | Coefficient of Friction | 0.05-0.15 | |

| Alloy Hardness | HB60~90 | Thermal Conductivity | 47W/(m ·k) | ||

| Coefficient of Thermal Expansion | 18 ·10-6K1 | ||||

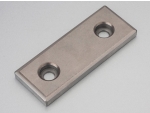

Structural Style of Customizable Product

Bushes, flanged bushes, thrust washers, slide plates, and the products required by the drawings of our customers.

BIM Size Specification

Application Characteristics

1. The BIM bimetallic bearing must be designed with oil lubrication. This product is usually fully sealed and added with grease when being assembled at low speed. It is refueled with oil plug when in use.

2. For instance, our product can be applied in the automobile balance bridge, spring steel seat hole, brake shoes, knuckle, movement rod, punch sliding part, and the bulldozer branch driver, etc.

3. If moved at medium speed, this product should be configured with oil cup for thin oil lubrication. It is proper for use in the connecting rod, transport wheel, and the revolving shaft of the punching and shearing machine, etc.

4. The bimetallic bearing is immersed in oil at high speed. For example, it can be used in the gearbox casing, oil pump, oil cylinder, engine, and the clutch, among others.

Chinese

Chinese English

English Português

Português Русский

Русский Español

Español Deutsch

Deutsch